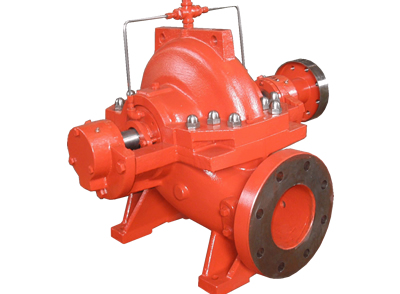

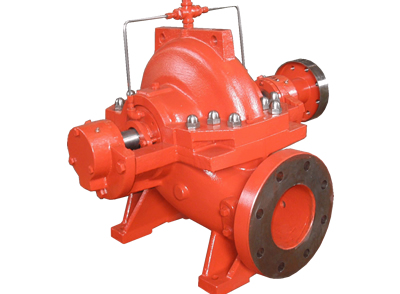

DFSS double suction split pump

The DFSS series double-suction split pump has a built-in sealed lubrication structure, and the sealed circulating water is more direct and effective for the lubrication and flushing of the sealed system. The linear appearance closes the pump cover with strong ribs, the built-in sealed and lubricated structure makes the overall structure of the pump integrated, and the flexible structure design makes the pump more exquisite and generous.

The DFSS series double-suction split pump has a built-in sealed and lubricated structure, and the sealed circulating water is more direct and effective for the lubrication and flushing of the sealed system. The straight-line appearance closes the pump cover with strong ribs, and the built-in sealed and lubricated structure makes the overall structure of the pump integrated.

DFSS double-suction split pump use:

It is mainly suitable for the occasions of transporting liquid in water plants, air-conditioning circulating water, building water supply, irrigation, drainage pumping stations, power stations, industrial water supply systems, fire fighting systems, shipbuilding and mining.

The suction port and discharge port of DFSS double-suction split pump body are under the pump body, so that the rotor can be taken out without disassembling the series of pipelines, which is convenient for maintenance. Most of the pump body adopts dual-channel design to reduce radial force. . Both the pump body and the pump cover are molded with resin sand board to ensure the appearance and size of the flow channel as well as the hydraulic efficiency of the pump (different from the general S and SH dry sand molding). The impeller is dynamically balanced to ensure the smooth operation of the pump and reduce noise. The shaft shortens the shaft spacing to extend the service life of the bearing and mechanical seal. The shaft is a fully sealed structure to ensure that it does not come into contact with the medium, does not rust, and has a long service life. The shaft sleeve can be made of a variety of different materials according to the needs of different users to prevent wear and corrosion of the shaft. The shaft seal adopts packing seal or mechanical seal, and the sealing device can be replaced without removing the pump cover. Bearing and lubrication adopt grease lubrication.

The transmission is driven by a motor through a flexible coupling. Rotation direction: seen from the drive end, it rotates clockwise.

Working conditions of DFSS double-suction split pump:

Flow rate: Q=50—16000m3/h Pump outlet caliber: DN=80—1000mm

Head: high H=160m working temperature: high T=105℃